Bronze

10 facts about bronze

With an entire era named after it, it probably would not occur to many that bronze has been used by man for the development of society for several millennia.

Here are a number of facts about bronze.

- Southern and Central Europeans have used bronze since 3000 BC and it was only around 1700 BC that the use of bronze became widespread in Northern Europe.

- Bronze is not a pure metal but, rather, is a common name for a series of copper alloys that can be divided into three main groups:

1) Leaded bronze: Copper alloyed with lead and tin, of approximately 2-7 % lead has been added.

2) Tin bronze: Copper alloyed with tin, often approximately 5-14 % tin has been added.

3) Alu bronze: Copper alloyed with aluminium, often approximately 6-11 % has been added.

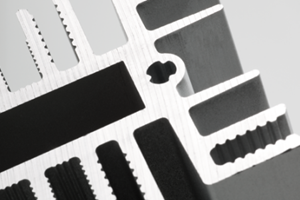

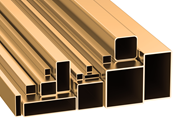

- Unlike other metals, such as aluminium and pure copper alloys, virtually all bronze is basically shaped via casting. The casting adds a special surface to “raw” bronze items such as blocks, rods and pipes but as soon as the material is processed, the colour and the metallic expression are revealed.

- Depending on the alloy, bronze can have a wide range of colours from yellowish to dark brown and more reddish.

- Generally, bronze is highly corrosion-resistant and this makes it an attractive choice in aggressive environments. However, the strength of the individual alloys differs significantly: Some alloys are characterised by e.g. high strength and hardness whereas others are characterised by good sliding properties, making them particularly suited for bearings.

- Bronze is characterised by being easy to machine and, thus, bronze is often available as rods that are used for machining, amongst others. However, it is important to be aware that the aluminium bronze alloys are not easily machined as they are much harder than most of the other bronze alloys.

- Due to the properties of bronze, typical applications are: Machine parts, wearing parts, engine parts, pumps, gears, valves and fittings.

- Bronze is also used in marine environments. Alu bronze is the category of bronze alloy that is most corrosion-resistant in connection with marine and aggressive environments with e.g. high pressures. Here, aluminium bronze can be used to advantage as these alloys are very resistant to wear. Classic applications for aluminium bronze are e.g. construction machinery and ship propellers.

- The vast majority of coins are made from bronze. By way of example, Danish coins consist of tin bronze (50-øre), nickel bronze (1-, 2- and 5-kroner) and alu bronze (10- and 20 kroner).

- Some types of bronze, including AMPCO® 8, AMPCO® 18 and AMPCO® M4, are food grade. In addition, these alloys are exceptionally durable and resistant to wear. These alloys are often used together with different types of steel alloys for e.g. bearings.