Copper

10 facts about copper

Since ancient times, man has known this reddish metal which, throughout history, has served as both an electrical transformer and a form of payment as a basis for war and destruction.

- From approximately 5000 BC, man has used copper as a utility metal and copper is therefore referred to as one of the ancient metals. Copper has been, and still is, used for a wide variety of purposes, such as coins, weapons, kitchen utensils, pipes, vessels and the sheathing of ships. Sheathing a ship means covering the part of the ship that is submersed in water. Sheathing ships with copper made it possible to sail tropical waters where the high water temperature combined with the salt and mineral levels of the water would normally corrode many other materials, including wood and various metals - but copper withstands these conditions and, thus, made sailing tropical waters a safe exploit as copper e.g. prevents mussels from growing on the keel.

- In Roman times, large quantities of copper were extracted in Cyprus and copper is therefore named after the Greek “Kyprus”. Later, the extraction of copper spread throughout the world and, in the 17th century, the world's largest copper mine was located in Falun, Sweden. Today, copper is mined in the United States and Chile, in particular.

- Copper is element number 29 in the periodic table and, with a density of 8.92 g/cm3 (20°C), it is considered a heavy metal. As an element, copper is also part of the structure of the cells of the human body and is also found in a wide variety of foods, such as meat, seafood, nuts and chocolate.

- The electric conductivity of pure copper is very high and, today, approximately two-thirds of all copper extracted are thus used as essential components of electrical applications e.g. in the form of wires. When describing the electric conductivity of other metals, pure copper is typically used as a reference for extremely good electric conductivity.

- Copper is also one of the very best metal heat conductors. This makes copper even more suitable for electric applications because copper quickly dissipates heat when conducting an electric current. Heat in the material creates resistance to the electric current which means that, because copper can quickly dissipate heat, the electric conductivity is also optimised. Most short-circuiting of electric appliances happen because they become overheated due to the current. Maybe you know it from your smartphone: Most modern smartphones are designed to turn off if they get overheated e.g. from lying in the sun.

- Copper alloys to which large amounts of other metals have been added have a lower electric conductivity than pure copper and these are widely used in connection with heat exchangers, pipes and decoration, such as interior design and building fronts.

- When copper comes into contact with atmospheric air, a thin layer of copper oxide forms on the copper surface. The copper oxide effectively protects the copper from further degradation/corrosion and, over time, the colour develops into the characteristic, evergreen colour you probably know from the roofs of older buildings or structures, such as church towers and statues. If desired, it is possible to speed up the formation of verdigris so that the material is covered in verdigris upon delivery or to encourage the greenish colour to quicker become prominent on the surface. This is especially popular in connection with facade constructions in which a dynamic and natural expression is desired.

- Copper is extremely mouldable which is a great advantage in the manufacture of electric applications, including wiring. Copper threads for wires are made by drawing the copper into small, thin threads. The many small threads are combined into individual wires and the more small threads in the wire, the greater the flexibility of the lead.

- Copper is extremely mouldable which is a great advantage in the manufacture of electric applications, including wiring. Copper threads for wires are made by drawing the copper into small, thin threads. The many small threads are combined into individual wires and the more small threads in the wire, the greater the flexibility of the lead.

- Both brass and bronze are copper alloys, i.e. copper mixed with large quantities of other metals. The different alloy combinations add a number of markedly different properties to the materials.

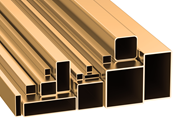

Our range of copper products